Innovations in Composite Materials: Real-World Applications

- Dec 8, 2023

- 9 min read

Introduction: Navigating the World of Composite Materials

Welcome to our in-depth exploration of composite materials and their transformative impact across various industries. Before delving into the details, here's a quick teaser of what you can expect from this comprehensive blog:

Aerospace Innovations: Discover how composite materials have revolutionized the aerospace industry, contributing to the development of lighter, more fuel-efficient aircraft with enhanced durability.

Architectural Breakthroughs: Learn about the role of composites in modern architecture and construction, enabling innovative designs, energy efficiency, and sustainability.

Automotive Advances: Uncover the shift towards composites in the automotive sector for creating safer, lighter, and more eco-friendly vehicles.

Renewable Energy Enhancements: See how composites are powering the future of renewable energy, particularly in wind power generation and efficient energy transmission.

Marine Industry Evolution: Dive into the marine world where composites are making waves by offering strength, reduced weight, and resistance to harsh environments.

Sports and Recreation Transformation: Explore the impact of composites in sports, enhancing the performance of athletes with equipment that is lighter, stronger, and more durable.

This blog offers a glimpse into the remarkable world of composite materials, showcasing how they are not just alternatives to traditional materials but pivotal in pushing the boundaries of innovation and sustainability. Get ready to embark on a journey through the fascinating realm of composites and their far-reaching applications!

Aerospace Industry

New Developments in Aerospace Composites

The aerospace industry is witnessing transformative advancements in material science, particularly with the emergence of bio-composites. These materials, derived from biological origins such as plants and biomass, offer a sustainable alternative to traditional composites. Bio-composites are increasingly used due to their advantages like being lightweight, flexible, cost-effective, and recyclable. These materials include natural fibers, biomass carbon fibers, and bio-resins, offering new possibilities for environmental performance in aircraft design.

Benefits

Weight Reduction: The lightweight nature of bio-composites significantly reduces the overall weight of aircraft, contributing to fuel efficiency.

Fuel Efficiency: By lowering the weight, these materials enable aircraft to consume less fuel, aligning with the goals of low-carbon aviation.

Enhanced Durability: The use of bio-composites in aircraft structures, like cabin and cargo areas, provides improved mechanical performance and durability, essential for enduring high structural loads.

Case Studies: Boeing 787 Dreamliner's Composite Structure

The Boeing 787 Dreamliner exemplifies the use of advanced composites in aerospace. This aircraft integrates carbon and glass fiber composites, which account for a significant portion of its structure, including the fuselage and wings. These materials contribute to the Dreamliner's reduced weight, increased fuel efficiency, and extended operational lifespan, showcasing the practical applications of these innovations in a real-world setting.

Architecture and Construction

Innovations in Composite Materials

Composite materials have become integral to modern architecture and construction, offering innovative solutions and new possibilities. These materials are engineered mixtures that turn ordinary substances into stronger, more sustainable compounds. They are used for their durability, flexibility, and resistance to environmental stressors.

Key Types and Uses

Granular Composites (Reinforced Concrete): Widely used in architecture for its strength and deformation resistance, important for building stability.

Fiber-Reinforced Composites: Include materials like Glass Fiber Reinforced Concrete (GFRC) and Carbon Fiber Reinforced Polymers (CFRP), known for their high strength-to-weight ratio. They are used in applications where weight and strength are critical, such as in large structures or areas requiring durability against environmental factors.

Laminates (Sandwich Composites): These are used for their lightweight and high-resistance properties, making them suitable for innovative architectural designs, including large, joint-free surfaces and complex shapes.

Benefits

Durability and Flexibility: Composites provide resistance to water damage, weather wear, and corrosion, extending the life of buildings and reducing repair needs.

Design Innovation: Allow for creative architectural designs without compromising safety. They enable the construction of large, light, and airy spaces.

Sustainability and Efficiency: Composites offer improved thermal energy performance and can contribute to a building's LEED certification.

Cost-Effectiveness: While initially more expensive than natural materials, composites offer long-term cost benefits through reduced maintenance and repair needs.

Applications in Architecture and Construction

Bridges: Composites are used for column strengthening, especially in earthquake-prone areas, due to their ductility and corrosion prevention properties.

Buildings and Civil Engineering: Used in structural integrated panels (SIPs), roofing shingles, and water piping systems. Glass-reinforced plastic in piping systems, for example, prevents erosion under high-pressure conditions.

Abstract Structures: Composites enable unique architectural designs, enhancing thermal energy performance and sustainability.

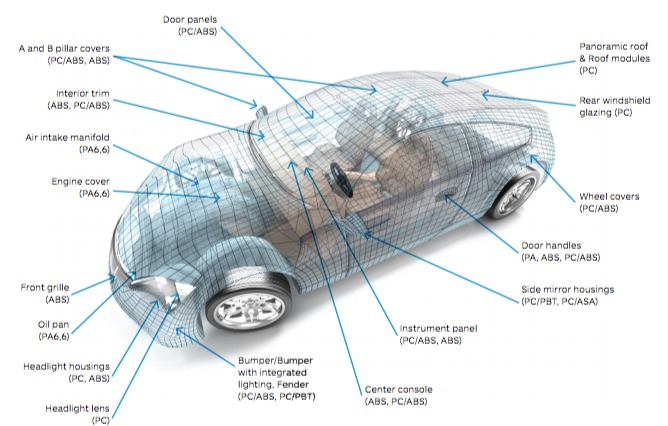

Automotive Sector

Innovations in Composite Materials

The automotive industry is increasingly incorporating composite materials to create lighter, safer, and more fuel-efficient vehicles. Composites, combining high-performance fibers like carbon or glass in a matrix material (like epoxy polymer), provide superior properties compared to the individual materials alone.

Key Developments and Applications

Green Composites: Recent innovations focus on sustainable "green composites" or biocomposites, derived from renewable resources like agricultural waste. These materials use natural fibers as reinforcing agents or bio-resins as the polymer matrix. Not only are they sustainable, but they also have a lower overall environmental impact compared to traditional polymer composites.

Lightweight and Strength: Carbon-fiber composites, which weigh about one-fifth as much as steel but offer comparable or better stiffness and strength, are gaining popularity. They do not corrode like steel or aluminum, significantly increasing vehicle fuel economy by potentially reducing vehicle weight by up to 60%.

Engineering for Crashworthiness: Composite materials, particularly sandwich composites (made by attaching thin composite facesheets to a thick, low-density core), are being studied for their crashworthiness. They can be designed to absorb more energy in a crash than traditional metallic materials, enhancing safety.

Bioconcept Cars: An example of innovation is the Bioconcept car, which uses body panels made from 100% natural fiber composites of hemp, flax, and jute, tested under extreme conditions for durability. Another example is the NanoCellulose Vehicle (NCV) from Japan, made almost entirely from composites containing wood fibers and exhibiting significant weight reduction and CO2 emission reduction.

Challenges and Future Prospects

Recycling and Disposal: A significant challenge lies in the disposal and recycling of polymer composite materials, especially given directives like the EU directive on end-of-life vehicles. This challenge is addressed by the push towards green composites, which are more easily recyclable and environmentally friendly.

Cost and Manufacturing: The use of composites in the automotive industry has historically been limited due to the high costs associated with materials and manufacturing. However, ongoing research and development aim to reduce these costs, making composites more viable for widespread use in the automotive sector.

Adoption in Mass-Produced Vehicles: While composites have been limited to low-production-volume vehicles or interior applications, there's a growing focus on mass-producing these materials for use in all aspects of next-generation vehicles.

Energy Production and Storage

Innovations in Composite Materials

In the field of renewable energy, composite materials are playing a crucial role, particularly in wind power generation. These materials are instrumental in making wind turbines more powerful and efficient, as well as enhancing the current capacity of power cables. The use of carbon fiber in turbine blades, for example, reduces their weight, allowing for longer blades which, in turn, increases the power output and efficiency of the wind turbines.

Key Applications

Wind Turbines: Carbon fiber composites are used in the spar caps of turbine blades to improve strength and reduce weight, leading to larger and more efficient turbines.

Power Transmission: Composite materials are being used to create High-Temperature Low-Sag (HTLS) conductors for power cables. These composite cored conductors can carry approximately twice the current of steel cored conductors at cooler operating temperatures, thus enhancing power transmission efficiency and reducing thermal sag.

Impact on Sustainable Energy

The integration of advanced composite materials in renewable energy infrastructure is a significant step towards a more sustainable future. These materials not only enhance the performance of renewable energy sources but also contribute to the more efficient transmission of power, thereby supporting the global transition to renewable energy sources.

Marine Applications of Composite Materials

Innovations and Developments

Composite materials have been increasingly embraced by the marine industry due to their advantageous properties over traditional materials like steel, wood, and aluminum. The use of composites in marine applications is not new, dating back to the 1970s with the production of the first fiberglass and polyester laminating resin boats using the hand lay-up process. However, the industry has seen significant advancements since then.

Key Applications

Boat Manufacturing: Composites have become a primary material for various boat components, such as hulls, decks, and liners. Their application ranges from outboard boats, stern drives, personal watercraft, yachts, and sailboats.

Advantages in Boat Design and Performance: The use of composites enhances mechanical properties, improves aesthetics, and enables innovation in shape and design, meeting boat owners' demands for looks and longevity.

Economic Impact: The marine composites market is closely tied to economic conditions. It is expected that the marine industry will consume composite materials to the tune of $1.5 billion in 2024, with an annual growth of over 5% in the next five years. The shift from aluminum to fiberglass has been significant, particularly in recreational fiberglass boat sales.

Recreational Boating Market: The recreational boating market, especially in regions like North America and Europe, is driving the demand for marine composites. This market is influenced by factors such as the rise in disposable income, growing middle class, and increased spending on leisure activities.

Dominant Materials in Marine Composites: Glass fibers, often used in the form of fabrics, are molded mainly with polyester and vinyl ester resins through resin infusion and open mold processes. Carbon fibers dominate the market for yachts, racer boats, and sailboats due to their high tensile strength.

Challenges and Future Prospects

While composites offer several benefits, they also present challenges. They are more expensive compared to traditional materials and lack standardization. Issues with maintenance, reparability, and recyclability also pose challenges, particularly in the commercial marine industry.

Sports and Recreation: The Role of Composite Materials

Composite materials have significantly impacted the sports and recreation industry. They offer advantages such as a higher strength-to-weight ratio compared to steel, corrosion resistance, and design flexibility, which are crucial in enhancing the performance of various sports equipment.

Applications in Sports Equipment

Diverse Equipment: Composites are used in a wide range of sports equipment, including fishing rods, tennis racquets, kayak paddles, windsurfing masts, hockey sticks, kites, and bicycle handlebars. These materials have replaced traditional wood and metal in many applications due to their superior properties.

Advantages in Use: The lightweight nature of composites, compared to wood, makes them easier to handle and work with, leading to reduced labor and equipment costs. Their dimensional stability ensures they retain their shape under various conditions, unlike wood, which can swell and shrink with humidity changes.

Lower Maintenance Costs: While the initial cost of composites may be higher, their longer lifecycles result in reduced long-term maintenance costs.

Enhanced Performance: The design flexibility offered by composites allows for the creation of equipment with complex shapes and geometries, which is not as easily achievable with traditional materials like steel or aluminum. Additionally, composites' resistance to elements is superior to aluminum, contributing to their durability in outdoor sports applications.

Reduced Weight: In sports where the weight of the equipment is critical, such as in racing or competitive events, composites offer an essential advantage by reducing the overall weight without compromising strength or performance.

Impact on Athlete Performance

The use of composites in sports equipment has helped athletes reach their highest performance potential. This is evident across various sports, from football helmets and golf clubs to bicycles and bobsleds. The superior properties of composites, such as their strength and lightweight nature, contribute significantly to enhancing the performance of athletes, enabling them to achieve new heights in their respective sports.

Conclusion: The Transformative Impact of Composite Materials Across Industries

The exploration of composite materials across various industries reveals their transformative impact and potential. These materials have proven to be not just alternatives to traditional materials but also enablers of innovation, efficiency, and sustainability.

Aerospace Industry: The use of composites in aerospace illustrates a leap in technological advancement, contributing to lighter, more fuel-efficient aircraft and enhanced durability.

Architecture and Construction: In construction, composites are revolutionizing building designs with their flexibility, sustainability, and design innovation, allowing for complex structures and energy-efficient buildings.

Automotive Sector: The automotive industry's shift towards composites is driven by the need for lighter, more fuel-efficient, and safer vehicles. This shift aligns with global sustainability goals and enhanced performance standards.

Energy Production and Storage: In renewable energy, particularly wind power, composites are key to creating more efficient and powerful turbines and improving power transmission capabilities.

Marine Applications: The marine industry's adoption of composites demonstrates their superiority in strength, weight reduction, and resistance to harsh marine environments, leading to more efficient and durable vessels.

Sports and Recreation: In the world of sports, composites have elevated the performance of athletes and recreational users alike by offering equipment that is lighter, stronger, and more durable.

Economic and Environmental Impact: Across these industries, composites not only offer economic advantages in terms of lifecycle costs and maintenance but also contribute to environmental sustainability by reducing carbon footprints and enhancing energy efficiency.

What's Next!

Discover the future of composite manufacturing with Addcomposites! Here's how you can get involved:

Stay Informed: Subscribe to our newsletter to receive the latest updates, news, and developments in AFP systems and services. Knowledge is power, and by staying informed, you'll always have the upper hand. Subscribe Now

Experience Our Technology: Try our cutting-edge simulation software for a firsthand experience of the versatility and capability of our AFP systems. You'll see how our technology can transform your production line. Try Simulation

Join the Collaboration: Engage with us and other technical centers across various industries. By joining this collaborative platform, you'll get to share ideas, innovate, and influence the future of AFP. Join Collaboration

Get Hands-On: Avail our educational rentals for university projects or semester-long programs. Experience how our AFP systems bring about a revolution in composite manufacturing and leverage this opportunity for academic and research pursuits. Request for Educational Rental

Take the Next Step: Request a quotation for our AFP systems. Whether you're interested in the AFP-XS, AFP-X, or SCF3D, we are committed to offering cost-effective solutions tailored to your needs. Take the plunge and prepare your production line for the next generation of composite manufacturing. Request Quotation

At Addcomposites, we are dedicated to revolutionizing composite manufacturing. Our AFP systems and comprehensive support services are waiting for you to harness. So, don't wait – get started on your journey to the future of manufacturing today!

References

Aerospace Industry

Airbus. (2021). This new class of materials could transform aircraft design. Retrieved from https://www.airbus.com

Architecture and Construction

Managing Composites. (n.d.). Composites in Architecture. Retrieved from https://managingcomposites.com

e-architect. (2020). Building with Composite Construction Materials. Retrieved from https://www.e-architect.com

ArchDaily. (2022). Future Materials: The Architecture of Biocomposites. Retrieved from https://www.archdaily.com

urdesignmag. (2023). Examples of Composite Materials in Architecture. Retrieved from https://www.urdesignmag.com

Automotive Sector

Mewburn Ellis LLP. (n.d.). Composites in automotive applications: accelerating towards a greener future? Retrieved from https://www.mewburn.com

Mechanical Engineering | University of Utah. (2012). Composites in Cars: Making Vehicles Lighter, Safer and More Fuel-Efficient. Retrieved from https://www.mech.utah.edu

Energy Production and Storage

Windpower Engineering & Development. (2020). Composites and renewable energy: Powering the future. Retrieved from https://www.windpowerengineering.com

Marine Applications

Stratview Research. (2019). Composite Materials in Marine Industry Witnessing Growth Waves. Retrieved from https://www.stratviewresearch.com

Composites One. (n.d.). The Marine Industry and Advanced Composites. Retrieved from https://www.compositesone.com

Sports and Recreation

Composites One. (n.d.). Composites in Sports and Recreation. Retrieved from https://www.compositesone.com

Discover Composites. (n.d.). Composites vs. Other Materials in Sports and Recreation. Retrieved from https://discovercomposites.com

Comments