How to Increase Research Freedom with Continuous Fiber Placement and Printing?

- Jun 24, 2022

- 4 min read

Updated: Jul 1, 2022

Freedom to digitally design structures with continuous fiber trajectories enables 10x enhanced structural and other properties, this presents an opportunity to utilize composites in even more industrial applications.

Research scholars working in this field have long waited to get access to such a system for testing new materials, optimizing structural constructions, gaining insight into the sustainable design of natural composites, etc. It is now possible to have a digital production system that can be installed in labs with little to no capital expenditure and in no time. Some possible research topics using the newly accessible system are discussed in this blog.

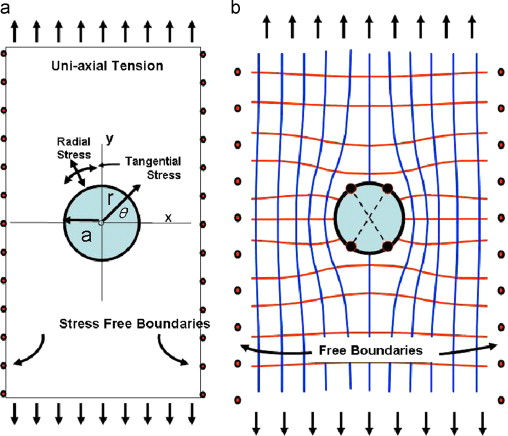

Stress concentration and fiber steering

Any structural component's main function is to allow smooth stress flow to enable the transfer of loads and moments from one end to another. Continuous fibers are the most efficient load-carrying members, acting as smooth channels for stresses to flow, without any breakage. The matrix material joining the fibers makes sure that all the stress flows are equally distributed among these fiber channels. In order to build the most effective composites structure needs to make sure the stress flow is continuous, smooth, and well-aligned without any breakage. To achieve this you want to have:

Well distributed fiber along the stress flow direction

Optimal fiber volume fraction (FVF) ratio

No porosity in the matrix

A good example of such optimization is needed around the holes in structures. Holes are stress concentrators, especially when drilled through precured fibers. Steering is able to significantly reduce fatigue and creep while increasing the strengths of structural elements. Traditionally, increasing the strength of an element meant increasing the part's thickness, thereby increasing its weight. Parts that are reinforced by stress flow trajectories (ie, steered fibers) according to stress distribution allow for much more efficient structures!

This approach in the research community is known as fiber steering, but the required equipment has been unobtainable by most research organizations.

Stiff and compliant wings with selective fiber placement

As explained in our beam bending blog, the external edges of beams experience the most bending stresses (tensile/compression), while the internal core is along the neutral axis, experiencing shear stresses. The most common structure to combat these stresses is the sandwich structure that is so often associated with composites, which creates the highest weight to stiffness ratio available today.

The key element in manufacturing with this approach is the core that can be 3D printed with any FDM printer in the desired surface configuration. The core needs to have a very good in-plane shear strength and so it should be printed vertically for best results. The free flow skin surface can be laid with stress flow optimization on top of the FDM printed core.

A very good example of this approach can be seen in the upcoming drones. The stress flow-optimized wing can be created that can provide wing control without hinges, by optimizing the placement of the fiber on the surface of the wing. The simplified construction with sustainable energy presents a much more affordable flying and cargo shipment experience.

Large area 3D printers: Light and strong structures

Fiber placement definitely provides many opportunities to optimize the fiber orientation and how it is placed according to conventional mechanics principles. The most underutilized aspect of fiber placement is the allocation of continuous material assets using selective fiber placement to deal with localized stresses.

An excellent example of this approach is where the FDM printed core is reinforced within the Z-direction of print, reinforcing layer-to-layer bonding with the fiber running across the layer, creating the economically lightweight and stiff structure that is

completely digitally produced.

Moonshot: Structural batteries [1]

Structural battery composites are a class of structural power composites aimed to provide mass-less energy storage for electrically powered structural systems. Structural battery composites are made from carbon fibers in a structural electrolyte matrix material. Neat carbon fibers are used as a structural negative electrode, exploiting their high mechanical properties, excellent lithium insertion capacity, and high electrical conductivity.

Lithium iron phosphate-coated carbon fibers are used as the structural positive electrode. Here, the lithium iron phosphate is the electrochemically active substance and the fibers carry mechanical loads and conduct electrons. The surrounding structural electrolyte is lithium-ion conductive and transfers mechanical loads between fibers. With these constituents, structural battery half-cells and full-cells are realized with a variety in device architecture.

The structural battery composite is a novel lightweight material. Not only is the density of the composite material constituents very low these constituents also demonstrate exceptional ability to perform two vital functions for lightweight.

Firstly, carbon fibers are stiff and strong, with unprecedented specific mechanical properties. Carbon fibers also have exceptional electrochemical characteristics, with very high specific capacity and coulombic efficiency.

Secondly, structural battery electrolytes are now available that can efficiently transfer mechanical loads and transport Li-ions. As consequence, numerous structural battery composite architectures can now be realized. Having said that, there is still little research performed on how to design and manufacture positive structural electrodes.

About Addcomposites

Addcomposites is the provider of the Automated Fiber Placement (AFP) ecosystem - including the Fiber Placement System (AFP-XS), 3D Simulation and Programming Software (AddPath), and Robotic Cells (AddCell). With the leasing program for the AFP system (AFPnext), composites manufacturers can work with thermosets, thermoplastics, dry fiber placement, or in combination with 3D Printers on a monthly basis.

References

Subscribe to the newsletter and get our guidebook - "Composites Manufacturing Methods: An Ultimate Guide for 2022"

Comments