Unleashing Metal and Ceramic Matrix Composites in Aerospace: Applications & Future Prospects

- May 23, 2023

- 7 min read

Updated: May 24, 2023

Introduction

Welcome to our blog post on metal and ceramic matrix composites in aerospace engineering! In this article, we will explore the significance and applications of these composite materials, providing a comprehensive overview. So, let's dive in!

Brief Overview of the Topic

Composite materials have revolutionized the aerospace industry, enabling the development of lightweight and high-performance structures. Metal Matrix Composites (MMCs) and Ceramic Matrix Composites (CMCs) are two types of composites that have garnered considerable attention for their exceptional properties and versatility.

Understanding the properties, applications, and ongoing developments in metal and ceramic matrix composites is essential for aspiring aerospace engineers. In this blog post, we will delve deeper into the characteristics, types, and applications of these composites, shedding light on their significance in the field.

So, let's explore the fascinating world of metal and ceramic matrix composites in aerospace engineering and discover the exciting possibilities they offer for the future of aircraft design and manufacturing!

Table of Content

Introduction

Brief overview of the topic

Importance of metal and ceramic matrix composites in aerospace engineering

Understanding Ceramic Matrix Composites (CMCs)

Definition and characteristics of CMCs

The potential of CMCs: high fracture toughness, resistance to catastrophic failure, high strength, light weight, low thermal expansion, high temperature and oxidation resistance

Types of bonds present in ceramics: ionic and covalent bonds

Common types of reinforcements for CMCs: silicon carbide (SiC), titanium carbide (TiC), boron carbide (B4C), silicon nitrides (Si3N4), boron nitrides (BN), alumina (Al2O3), zirconia (ZrO2), and carbon (graphite or partially amorphous) and boron

Types of Matrices

Ceramic matrices

Fiber-matrix interfacial domain

Common matrices: glasses, glass ceramics, carbon, SiC, Si3N4, aluminates, and oxides

Understanding Metal Matrix Composites (MMCs)

Definition and characteristics of MMCs

Types of metallic matrices used in MMCs: aluminium, magnesium, titanium, copper, etc.

Typical reinforcements for MMCs: ceramic particles or fibers, carbon fibers, and metallic fibers

Processing techniques for MMCs: liquid metal and powder metallurgy

Advantages of MMCs: high transverse strength and stiffness, high ductility and fracture toughness, high temperature and fire resistance

Applications of MMCs

Various applications of MMCs: from cutting tools to tank armors, brake discs, propulsion shafts, bicycle frames, and more

Specific applications of MMCs in the aerospace industry

Current Research Objectives for MMCs

Increase yield and tensile strength at different temperatures

Increase creep resistance at higher temperatures

Improve thermal shock resistance, corrosion resistance, and Young’s modulus

Reduce thermal expansion

Conclusion

Recap of the importance and applications of metal and ceramic matrix composites in aerospace engineering

Future prospects and developments in the field

Understanding Ceramic Matrix Composites (CMCs)

Ceramic Matrix Composites, often abbreviated as CMCs, are a type of composite material that has gained significant attention in the aerospace industry due to their unique properties. They are particularly known for their high fracture toughness, resistance to catastrophic failure, high strength, lightweight, low thermal expansion, and ability to withstand high temperatures with high oxidation resistance.

Let's break down some of these characteristics:

High Fracture Toughness: CMCs are able to absorb significant energy before fracturing, making them highly durable and resistant to cracks.

Resistance to Catastrophic Failure: Unlike other materials that can fail suddenly and without warning, CMCs tend to fail gradually, allowing for early detection and prevention of complete failure.

High Strength: CMCs are incredibly strong, making them suitable for applications that require materials to withstand high levels of stress.

Light Weight: Despite their strength, CMCs are relatively lightweight, making them ideal for aerospace applications where weight is a critical factor.

Low Thermal Expansion: CMCs have a low coefficient of thermal expansion, meaning they don't expand or contract significantly with temperature changes. This is crucial in aerospace applications where materials are subjected to extreme temperature variations.

High Temperature and Oxidation Resistance: CMCs can withstand extremely high temperatures and resist oxidation, making them suitable for applications like jet engines that operate in high-temperature environments.

CMCs are typically composed of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix can withstand high temperatures, making CMCs ideal for applications that require thermal resistance.

The bonds present in ceramics can be of two types: ionic and covalent. Ionic bonding occurs between metallic and nonmetallic elements, while covalent bonding happens when atoms share electrons.

Common types of reinforcements for CMCs include silicon carbide (SiC), titanium carbide (TiC), boron carbide (B4C), silicon nitrides (Si3N4), boron nitrides (BN), alumina (Al2O3), zirconia (ZrO2), and carbon (graphite or partially amorphous) and boron. These reinforcements enhance the overall properties of the CMCs.

Understanding the properties and composition of CMCs is crucial for their effective use in aerospace engineering. As we continue to innovate and push the boundaries of what's possible in aerospace, CMCs will undoubtedly play a key role in the future of this exciting field.

Types of Matrices in CMCs

In composite materials, the matrix plays a crucial role in determining the overall properties of the material. It binds the reinforcement together, transfers stresses between the reinforcing fibers/particles, and protects the reinforcement from environmental damage. Let's take a closer look at the types of matrices used in composites, with a particular focus on ceramic matrices.

Ceramic Matrices

Ceramic matrices are commonly used in both Ceramic Matrix Composites (CMCs) and Metal Matrix Composites (MMCs). They are nonmetallic inorganic materials, composed of metallic and nonmetallic elements connected by ionic and/or covalent bonds.

Some of the common ceramic matrices include:

Oxide Ceramics: Oxide ceramics, such as alumina (Al2O3) and zirconia (ZrO2), are commonly used as matrices in CMCs. They offer good thermal stability, high strength, and resistance to corrosion.

Glass Ceramics: Glass ceramics are materials that are initially produced as glasses but are then crystallized to form a microstructure with ceramic-like properties. They provide a balance between the toughness of glasses and the strength of ceramics, making them suitable for certain CMC applications.

Carbon: Carbon-based matrices, such as carbon/carbon composites, are widely used in CMCs due to their excellent high-temperature resistance, low thermal expansion, and good mechanical properties. They are particularly suitable for applications where weight reduction is critical.

Silicon Carbide (SiC): SiC matrices offer excellent mechanical strength, high-temperature stability, and resistance to thermal shock. They are commonly used in CMCs for applications that require superior strength and high-temperature resistance.

Silicon Nitride (Si3N4): Si3N4 matrices exhibit high strength, excellent thermal shock resistance, and good resistance to oxidation. They are commonly used in CMCs for aerospace applications that require high-temperature performance.

Aluminates: Aluminates, such as aluminum titanate (Al2TiO5), are used as matrices in certain CMCs due to their thermal stability, low thermal expansion, and resistance to thermal shock.

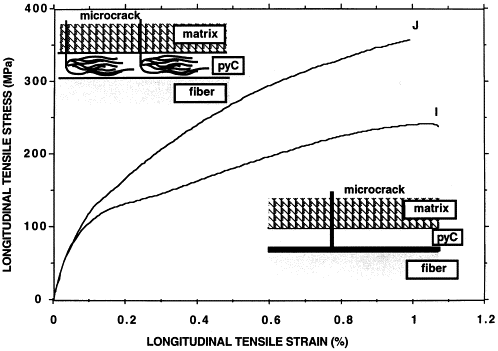

Fiber-Matrix Interfacial Domain

The fiber-matrix interfacial domain is the region where the fibers (or particles) and the matrix material interact. This interface plays a crucial role in determining the overall properties of the composite. It can consist of an interface or an interphase. Interphase implies the presence of at least two interfaces: one with the matrix and one with the fiber, and more when the interphase consists of a multilayer.

Understanding the types of matrices used in composites and the role of the fiber-matrix interface is crucial for anyone working with these materials. As we continue to innovate and develop new composite materials, the choice of matrix and the design of the fiber-matrix interface will continue to play a key role in determining the properties and potential applications of these materials.

Understanding Metal Matrix Composites (MMCs)

Metal Matrix Composites, often referred to as MMCs, are another category of composite materials that have found extensive use in the aerospace industry. They are made up of a metal matrix that is reinforced with a different material, often ceramic particles or fibers, carbon fibers, or metallic fibers.

Here are some key characteristics of MMCs:

High Transverse Strength and Stiffness: MMCs are known for their high strength and stiffness, especially in directions perpendicular to the direction of applied force. This makes them ideal for applications that require materials to withstand high levels of stress from multiple directions.

High Ductility and Fracture Toughness: Unlike some other composite materials, MMCs exhibit high ductility, meaning they can deform significantly before breaking. This, combined with their high fracture toughness, makes them resistant to cracks and fractures.

High Temperature and Fire Resistance: MMCs can withstand high temperatures and are resistant to fire, making them suitable for applications that operate in high-temperature environments, such as jet engines.

MMCs are typically made using a variety of metallic matrices. Some of the most common ones include aluminum, magnesium, titanium, and copper. The choice of matrix material depends on the specific requirements of the application. The reinforcements used in MMCs can be ceramic particles or fibers, carbon fibers, or metallic fibers. These reinforcements enhance the overall properties of the MMCs, making them stronger, stiffer, and more resistant to heat and wear.

There are several processing techniques used to manufacture MMCs. Two of the most common ones are liquid metal processing and powder metallurgy. Liquid metal processing involves mixing the reinforcement material with molten metal, while powder metallurgy involves mixing metal powder with the reinforcement material and then heating the mixture to form a solid composite. Understanding the properties and composition of MMCs is crucial for their effective use in aerospace engineering. As we continue to innovate and push the boundaries of what's possible in aerospace, MMCs will undoubtedly play a key role in the future of this exciting field.

Applications and Current Research Objectives of MMCs

MMCs have a wide range of applications due to their unique properties such as high strength, high ductility, and resistance to high temperatures. They are used in various industries, including the aerospace industry, where their properties are particularly beneficial.

Applications of MMCs

MMCs are used in a variety of applications, including:

Cutting Tools: MMCs are often used to make cutting tools due to their high strength and resistance to wear.

Tank Armors: The high strength and toughness of MMCs make them ideal for use in tank armors.

Brake Discs: MMCs are used in brake discs in both the automotive and railway industries due to their high heat resistance and strength.

Propulsion Shafts: In the aerospace industry, MMCs are used in propulsion shafts due to their high strength and lightweight.

Bicycle Frames: The lightweight and high strength of MMCs make them an excellent material for bicycle frames.

Current Research Objectives for MMCs

Research is ongoing to further improve the properties of MMCs and expand their potential applications. Some of the current research objectives include:

Increasing Yield and Tensile Strength: Researchers are working on ways to increase the yield and tensile strength of MMCs at different temperatures.

Increasing Creep Resistance: Efforts are being made to increase the creep resistance of MMCs at higher temperatures compared to conventional alloys.

Improving Thermal Shock Resistance: One of the goals of current research is to improve the thermal shock resistance of MMCs.

Improving Corrosion Resistance: Research is also focused on improving the corrosion resistance of MMCs.

Increasing Young’s Modulus and Reducing Thermal Expansion: Researchers are working on ways to increase Young’s modulus of MMCs and reduce their thermal expansion.

Understanding the applications and current research objectives of MMCs is crucial for recent graduates in the industry. As we continue to innovate and push the boundaries of what's possible in aerospace, MMCs will undoubtedly play a key role in the future of this exciting field.

Conclusion

Metal Matrix Composites (MMCs) and Ceramic Matrix Composites (CMCs) have emerged as crucial materials in the field of aerospace engineering. Their unique properties and versatility make them highly desirable for various applications. Let's recap the importance and applications of these composites and explore future prospects in the field.

Importance and Applications

MMCs: MMCs offer exceptional strength, stiffness, and temperature resistance, making them valuable in aerospace applications. Some specific uses include:

Cutting tools that require high strength and wear resistance.

Tank armor demands superior toughness and protection.

Brake discs for automotive and railway systems due to their high heat resistance.

Propulsion shafts in aerospace, benefit from their strength and lightweight characteristics.

Bicycle frames require both strength and lightness for performance.

CMCs: CMCs possess remarkable fracture toughness, resistance to catastrophic failure, and thermal stability. Their applications include:

Aircraft engine components, where high-temperature resistance and durability are essential.

Thermal protection systems, such as CMCs can withstand extreme heat during reentry into the Earth's atmosphere.

Aerospace structural elements benefit from their strength-to-weight ratio.

Future Prospects and Developments

The field of composite materials in aerospace engineering continues to evolve, and future prospects are promising. Here are some developments to look forward to:

Advancements in Material Properties: Ongoing research aims to enhance the yield and tensile strength of MMCs at different temperatures while improving creep resistance. Efforts are also focused on improving the thermal shock resistance, corrosion resistance, and Young's modulus of MMCs.

Innovative Manufacturing Techniques: Further advancements in manufacturing techniques, such as additive manufacturing (3D printing) and advanced forming processes, will enable the production of complex shapes and structures with improved efficiency and reduced costs.

New Material Combinations: Exploration of novel combinations of matrices and reinforcements will expand the range of properties achievable in composites. This will open up new possibilities for aerospace applications, including increased toughness, enhanced electrical conductivity, and improved thermal management.

Sustainability and Environmental Considerations: Future developments will also emphasize sustainable manufacturing processes and the recyclability of composite materials to reduce environmental impact and support a more sustainable aerospace industry.

Comments